| Place of Origin | India |

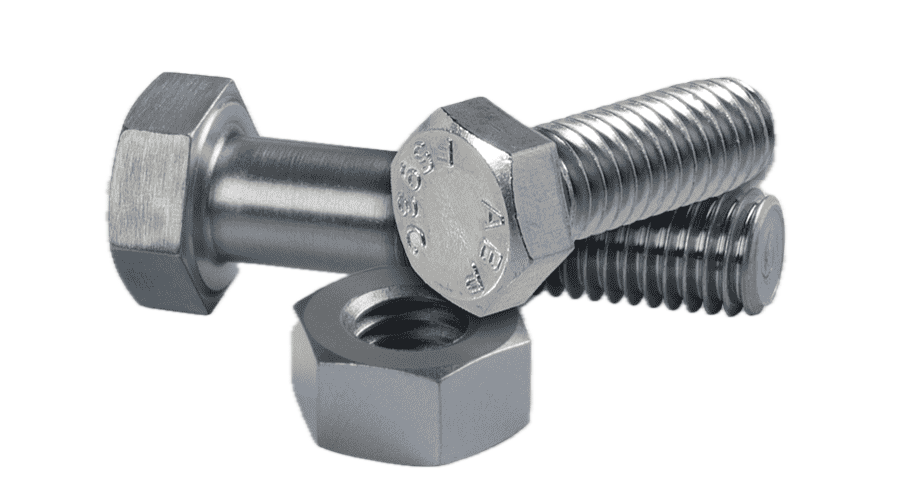

| High Tensile Bolts Grades | High Tensile Bolts Grade 8.8, High Tensile Bolts Grade 12.9, High Tensile Bolts Grade 10.9 |

| Standard | IS / BS / BSW / DIN / ASME / ASTM, ISO 4017, DIN931, GB5783, DIN, ASTM, ANSI, JIS, EN, AS |

| DIN Standard | B.S. DIN933, DIN931, DIN934, DIN912, DIN603, DIN6923 |

| Surface treatment | Passivation/plain |

| High Tensile Bolts Size | M2 – M100 |

| High Tensile Bolts Diameter | M3 – M60 |

| High Tensile Bolts Length | 6mm – 500mm |

| Head | Hex, Square, Round, Hex flange, Flat, T-head, Triangular, etc. |

| Neck type | Hex, Square, Triangular, Oval, Knurled, etc. |

| High Tensile Bolts Drive Type | Phil, Slotted, Hex socket, Torx, Square slot, etc. |

| High Tensile Bolts Material | 1. Stainless Steel: SS201, SS303, SS304, SS316, SS410, SS420 2. Steel: C45(K1045), C46(K1046), C20 3. Brass: C36000 (C26800), C37700 (HPb59), C38500 (HPb58) 4. Bronze: C51000, C52100, C54400, etc. 5. Iron: 1213, 12L14, 1215 6. Aluminum: Al6061, Al6063, etc. 7. Carbon steel: C1006, C1010, C1018, C1022, C1035K, C1045 8. Alloy steel: SCM435, C10B21, C10B33 |

| High Tensile Bolts Application | Wind tower, Nuclear power, Railway, Automotive industry, Construction, Electronic industry |

| High Tensile Bolts Dimensions | ASME B18.6.3 (Exception: screws 6 inches and shorter are fully threaded) |

| Thread Requirements | ASME B1.1, UNC & UNF, Class 2A (Fastenal will inspect and accept parts with a 1A no-go gauge) |

| High Tensile Bolts Finish | Per ASTM A380/A380M |

| High Tensile Bolts Finishing | Zinc Plated (Yellow, White, Blue, Black), Passivated, Hot Dip Galvanized (HDG), Phosphorization, Black Oxide, Geomet, Dacroment, Sandblast, Anodize, Chromate, Electro Painting, Black Anodize, Chrome plated, Nickel plated, Zinc-Nickel plated, Brass Plated, Tin Plated, Black Plated, Copper Plated, Gold Plated, Salt fog test |

| Stock Products | Stainless steel: All DIN, GB Standard, and part ANSI standard High Tensile Bolts, Example: ISO7380, DIN7981, DIN7982, DIN916, DIN913, DIN7985, DIN912 |

| Production technology | Cold Forged |

| Manufacturing Process | Wire Drawing, Cold Heading, Insert Tapping, Heat Treatment, Surface Plating, Inspection, Packing |

| MOQ | 10 pieces |

| Delivery time | Regular product: 7-15 days, Custom product: as per special requirement |

| Others | OEM, ODM, ±0.03MM tolerance |

| Surface treatment of High Tensile Bolts | Passivation, Polish, Anodizing, Sand Blasting, Electroplating (Color, Blue, White, Black Zinc, Ni, Cr, Tin, Copper, Silver), Black Oxide Coating, Heat-disposing, Hot-Dip Galvanizing, Preventive Oil |

| High Tensile Bolts Coatings | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Tolerance of High-Tensile Bolts | +/- 0.01mm to +/- 0.05mm |

| High Tensile Bolts Samples | Yes |

| Production Capacity | 2,700,000 pieces per month |

| Payment Terms | T/T, PayPal, Western Union, L/C, or Trade Assurance. 30% deposit & balance before shipping |

| Specialized in | Passivation, Polish, Anodizing, Sand Blasting, Electroplating (Color, Blue, White, Black Zinc, Ni, Cr, Tin, Copper, Silver), Black Oxide Coating, Heat-Disposing, Hot-Dip Galvanizing, Preventive Oil |